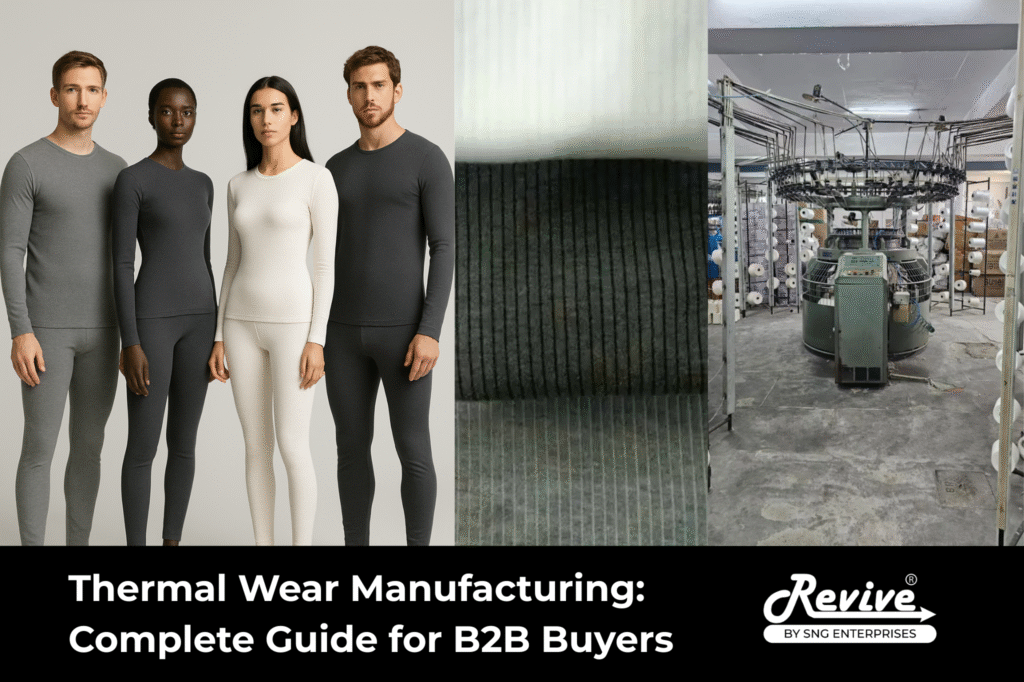

Introduction

Thermal wear plays a vital role in the global winter apparel market. From thermal innerwear India to bulk thermal wear Ludhiana exports, the demand for warm, lightweight, and durable winter clothing continues to grow every year.

India, particularly Ludhiana in Punjab, has built a strong reputation as the hosiery and thermal wear capital of the country. Wholesalers, retailers, and fashion brands worldwide source from this hub because of its expertise, affordability, and manufacturing scale.

But for B2B buyers, the challenge isn’t just finding a supplier—it’s finding the right partner who ensures quality, consistency, and timely delivery. This guide walks you through everything you need to know about sourcing thermal wear in India, from manufacturing processes and fabrics to supplier evaluation and future market trends.

1. Why India is a Global Hub for Thermal Wear

India is one of the largest producers of textiles and apparel worldwide, with winter wear India exports increasing year after year. Here’s why global brands and wholesalers prefer India:

1.1 Expertise and Legacy

Cities like Ludhiana in Punjab have been at the forefront of hosiery and winter wear for decades. Generational businesses bring unmatched skill in knitting, finishing, and garment construction.

1.2 Cost Advantage

Compared to sourcing from China, Turkey, or Bangladesh, thermal wear manufacturers Punjab offer competitive pricing without compromising on quality—ideal for both startups and bulk buyers.

1.3 Diverse Range

From cotton thermal innerwear India to premium wool blends for exports, buyers can source everything under one roof.

1.4 Export-Friendly Ecosystem

With strong logistics, government support, and compliance-ready suppliers, thermal wear exporters Punjab serve markets across Europe, North America, and the Middle East.

1.5 Sustainable Manufacturing

A growing number of suppliers now specialize in eco-friendly thermal wear India, using organic cotton, recycled yarns, and ethical practices.

2. Step-by-Step Thermal Wear Manufacturing Process in India

Understanding the process helps buyers evaluate supplier capabilities.

- Yarn Selection

- Cotton (breathable, comfortable for India).

- Polyester blends (lightweight, moisture-wicking).

- Wool blends (premium, export-oriented).

- Organic cotton (sustainable alternative).

- Cotton (breathable, comfortable for India).

- Knitting

- Single jersey fabric India → soft and stretchable.

- Rib fabric suppliers Punjab → durable and flexible.

- Interlock fabric India → thicker, warmer, ideal for winter thermals.

- Single jersey fabric India → soft and stretchable.

- Dyeing & Finishing

- Pre-shrunk fabrics for size stability.

- Colorfastness testing for long-lasting shades.

- Anti-pilling treatments for durability.

- Pre-shrunk fabrics for size stability.

- Cutting & Stitching

- Flatlock stitching ensures strength and comfort.

- Specialized machines maintain uniformity.

- Flatlock stitching ensures strength and comfort.

- Quality Control

- Thermal insulation tests.

- Fabric stretch and recovery checks.

- Final inspections before bulk dispatch.

- Thermal insulation tests.

- Packaging & Dispatch

- Bulk thermal wear India packed for wholesalers.

- Export-ready packaging with labeling compliance.

- Bulk thermal wear India packed for wholesalers.

3. Types of Thermal Fabrics & Technologies

Different buyers prefer different fabric technologies:

- Cotton Thermals → Soft, breathable, ideal for Indian winters.

- Polyester Blends → Lightweight, moisture-wicking, quick-dry.

- Wool Blends → High insulation, premium export category.

- Organic Cotton Thermals → Growing demand in Europe & North America.

- Knitted Innovations → Ribbed, interlock, and brushed fleece fabrics enhance warmth.

4. Key B2B Sourcing Considerations

When choosing a supplier, evaluate beyond pricing.

- Fabric Quality & Certifications – OEKO-TEX, ISO.

- MOQ Flexibility – Startups vs large wholesalers.

- Lead Times – Consistency in seasonal deliveries.

- Scalability – Ability to handle large winter orders.

- Location Advantage – Ludhiana hosiery wholesale hubs reduce cost and time.

5. Market Trends 2025–2026

The global thermal wear market is evolving. Key trends:

- Eco-Friendly Demand – Surge in organic cotton fabric India for sustainable thermals.

- Private Label Growth – More brands seeking thermal innerwear India under custom branding.

- Export Expansion – Thermal clothing Punjab suppliers increasing reach to US, Europe, Middle East.

- Blended Fabrics – High-performance cotton-polyester blends for durability and comfort.

6. Buyer’s Checklist for Thermal Wear Sourcing

Before finalizing a manufacturer, check:

- Do they provide fabric samples for testing?

- Are they certified (ISO, OEKO-TEX)?

- What is their MOQ for bulk thermal wear Ludhiana supply?

- Do they have export experience?

- Can they offer eco-friendly thermal wear India?

Explore Thermal Wear Collection

7. Why Revive by SNG Enterprises is a Trusted Thermal Wear Partner

For over 50 years, Revive by SNG Enterprises has been a pioneer in knitted fabrics India and thermal wear manufacturing Punjab. As a 3rd-generation family business based in Ludhiana, we’ve built trust with wholesalers, exporters, and private labels worldwide.

Our Specializations

- Cotton and organic cotton thermals.

- Single jersey, rib, and interlock fabrics for thermal wear.

- Private label thermal innerwear for global brands.

- Bulk thermal wear exports to Europe, North America & Middle East.

What Sets Us Apart

- End-to-end solutions: yarn → fabric → garment.

- Flexible MOQs to support startups and wholesalers.

- Commitment to sustainability and eco-friendly manufacturing.

- Proven track record in Ludhiana hosiery wholesale exports.

Contact us at +91 98724-32426

Visit Thermal Wear Collection

FAQs

1. What fabrics are most used in thermal wear India?

Cotton, polyester blends, wool, and organic cotton are widely used, depending on market needs.

2. Which city is famous for thermal wear manufacturers Punjab?

Ludhiana is India’s biggest hosiery and thermal wear hub, known for bulk sourcing and exports.

3. Do Indian manufacturers export thermal innerwear globally?

Yes, suppliers from Punjab ship to Europe, the US, and the Middle East.

4. Can I order small MOQs from wholesale thermal wear India suppliers?

Yes, companies like Revive by SNG Enterprises offer MOQ flexibility for startups and wholesalers.

5. Is eco-friendly thermal wear India available?

Absolutely. Organic cotton and recycled blends are available with leading suppliers.

Conclusion

India’s thermal wear industry is a powerhouse, combining affordability, skilled craftsmanship, and export-readiness. For B2B buyers, Ludhiana remains the top sourcing destination, offering everything from cotton thermals to eco-friendly winter wear.

By understanding the manufacturing process, fabrics, and sourcing best practices, buyers can make informed decisions and build long-term partnerships. And with its 50+ year legacy in knitted fabrics and thermals, Revive by SNG Enterprises is ready to be your trusted partner for growth.

Contact: +91 98724-32426

Explore Thermal Wear Collection

Author Bio

Written by: Sambhav Gupta

Sambhav Gupta is a Partner at SNG Enterprises and co-founder of Revive by SNG, where he plays a key role in driving growth, product development, and strategic partnerships. With a strong focus on sustainability and innovation, Sambhav is passionate about expanding SNG’s global footprint and offering fabrics that balance quality, scalability, and environmental responsibility.